Hauv kev ua haujlwm precision machining, kev xaiv cov cuab yeej txiav tuaj yeem cuam tshuam rau qhov zoo ntawm cov khoom tiav, qhov ua tau zoo ntawm cov txheej txheem machining thiab tag nrho cov nqi tsim khoom. Ntawm cov cuab yeej no, kev tig cov ntxig ua lub luag haujlwm tseem ceeb hauv kev ua tiav cov txiaj ntsig zoo tshaj plaws. Hauv cov blog no, peb'yuav tshawb nrhiav qhovqhov zoo tshaj plaws tig inserts nyob rau hauv kev ua lag luam, lawv cov yam ntxwv, thiab yuav ua li cas xaiv cov ntxig rau koj cov kev xav tau tshwj xeeb.

Kawm txog kev tig cov ntxig

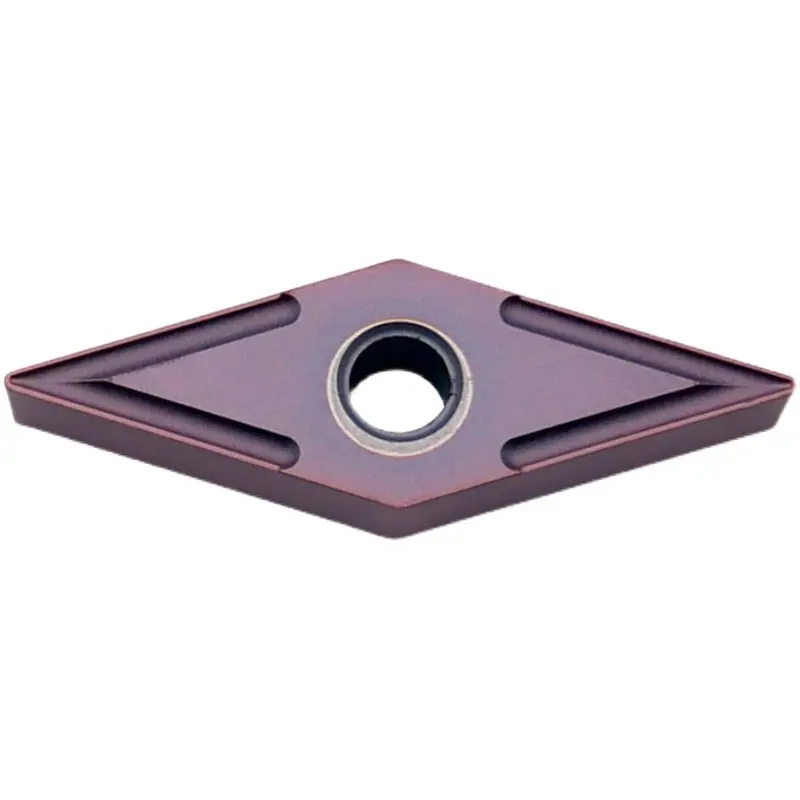

Cov cuab yeej txiav yog cov cuab yeej me me, hloov tau siv rau ntawm lub tshuab dhos thiab lub tshuab dhos los ua kom zoo nkauj thiab ua tiav cov ntaub ntawv xws li hlau, yas thiab ntoo. Lawv muaj ntau yam duab, qhov loj me thiab cov ntaub ntawv, txhua tus tsim rau ib daim ntawv thov tshwj xeeb. Cov cuab yeej txiav zoo tuaj yeem txhim kho kev ua haujlwm txiav, txhim kho qhov tiav ntawm qhov chaw thiab ua kom lub cuab yeej siv tau ntev, yog li kev xaiv qhov kev xaiv zoo tshaj plaws rau koj qhov project yog qhov tseem ceeb heev.

Cov yam ntxwv tseem ceeb ntawm cov ntxig tig zoo tshaj plaws

1. Cov Khoom Siv Muaj pes tsawg leeg:Cov khoom siv ntawm koj lub cuab yeej tig yog ib qho tseem ceeb tshaj plaws uas yuav tsum xav txog. Cov khoom siv feem ntau suav nrog carbide, ceramics, cermets, thiab high-speed steel (HSS). Carbide inserts nrov rau lawv qhov nyuaj thiab hnav tsis kam, ua rau lawv haum rau kev siv tshuab ceev ceev. Cov hniav ceramic, ntawm qhov tod tes, zoo tagnrho rau kev siv kub siab.

2. TXHUAM:Muaj ntau cov hniav uas siv rau kev tig tau coated los txhim kho lawv txoj kev ua haujlwm. Cov txheej txheej xws li TiN (titanium nitride), TiAlN (titanium txhuas nitride) thiab TiCN (titanium carbonitride) tuaj yeem txhim kho kev hnav tsis kam, txo kev sib txhuam thiab ua kom lub cuab yeej siv tau ntev. Xaiv cov hniav uas coated rau kev ua haujlwm zoo dua hauv cov xwm txheej machining nyuaj.

3. Geometry:Qhov geometry ntawm ib qho ntxig (xws li nws cov duab, lub kaum sab xis ntawm ntug txiav thiab kev tsim cov chipbreaker) ua lub luag haujlwm tseem ceeb hauv nws qhov kev ua tau zoo ntawm kev txiav. Cov hniav positive rake zoo tagnrho rau cov khoom mos dua, thaum cov hniav negative rake zoo dua rau cov khoom tawv dua. Tsis tas li ntawd, kev tsim cov chip breaker tuaj yeem pab tswj cov chip ntws thiab txhim kho qhov tiav ntawm qhov chaw.

4. Qhov Loj thiab Duab:Cov ntxig tig muaj ntau yam duab, suav nrog plaub fab, peb ceg, thiab puag ncig. Kev xaiv cov duab nyob ntawm qhov kev ua haujlwm tig thiab geometry ntawm cov khoom ua haujlwm. Piv txwv li, cov ntxig plaub fab yog ntau yam thiab tuaj yeem siv rau ob qho tib si roughing thiab finishing ua haujlwm, thaum cov ntxig puag ncig yog qhov zoo tagnrho rau kev ua tiav.

Cov Hom Lag Luam Zoo Tshaj Plaws thiab Lawv Cov Ntxig Tig Zoo Tshaj Plaws

1. Sandvik Coromant:Paub txog nws cov cuab yeej txiav tshiab, Sandvik muaj ntau yam khoom siv tig zoo. Lawv cov GC series ntawm cov carbide inserts nrov tshwj xeeb rau lawv qhov kev hloov pauv tau yooj yim thiab kev ua tau zoo hauv ntau yam khoom siv.

2. Kennametal:Kennametal yog lwm lub npe lag luam ua lag luam hauv kev lag luam cuab yeej txiav. Lawv cov koob KCP ntawm cov ntxig tau tsim los rau kev siv tshuab ceev ceev thiab muaj kev tiv thaiv kev hnav zoo heev, ua rau lawv nyiam ntawm cov chaw tsim khoom.

3. Walter Cov Cuab Yeej:Walter cov cuab yeej tig tau paub txog lawv qhov kev ua haujlwm raug thiab ruaj khov. Cov koob Walter BLAXX muaj cov qauv geometries thiab cov txheej txheem siab heev los txhim kho kev ua haujlwm hauv qab cov xwm txheej machining hnyav.

4. Iscar:Iscar'Cov ntxig tig tau tsim los rau kev ua haujlwm zoo thiab kev tsim khoom. Nws cov IC series muaj ntau yam geometries thiab coatings kom haum rau ntau yam kev siv.

Xaus lus

Kev xaiv cov hniav tig zoo tshaj plaws yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig zoo tshaj plaws. Los ntawm kev xav txog cov yam xws li cov khoom siv sib xyaw, txheej, geometry, thiab lub koob npe nrov ntawm lub npe, koj tuaj yeem xaiv cov hniav kom raug rau koj cov kev xav tau tshwj xeeb. Kev nqis peev rau cov hniav tig zoo tsis yog tsuas yog txhim kho qhov zoo ntawm koj txoj haujlwm xwb, tab sis kuj ua rau muaj kev tsim khoom ntau ntxiv thiab txo cov nqi tag nrho. Txawm hais tias koj yog tus kws kho tshuab uas muaj kev paub dhau los lossis tshiab rau kev lag luam, kev nkag siab txog qhov sib txawv ntawm cov hniav tig yuav ua rau koj txiav txim siab tau zoo thiab coj koj cov haujlwm machining mus rau qhov siab tshiab.

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-11-2024