Hauv ntiaj teb kev siv tshuab, qhov tseeb thiab kev ua tau ntau yam yog qhov tseem ceeb tshaj plaws. Ib qho cuab yeej uas muaj cov yam ntxwv no yog lub pob zeb kawg. Cov cuab yeej txiav tshwj xeeb no nrov nrog cov kws kho tshuab thiab cov chaw tsim khoom vim nws muaj peev xwm tsim cov duab thiab cov duab sib txawv nrog qhov tseeb zoo kawg nkaus. Hauv cov blog no, peb yuav tshawb nrhiav cov haujlwm, kev siv, thiab cov txiaj ntsig ntawm cov pob zeb kawg los qhia txog vim li cas lawv thiaj li yog ib qho tseem ceeb ntawm cov txheej txheem siv tshuab niaj hnub.

Lub tshuab zeb kawg pob yog dab tsi?

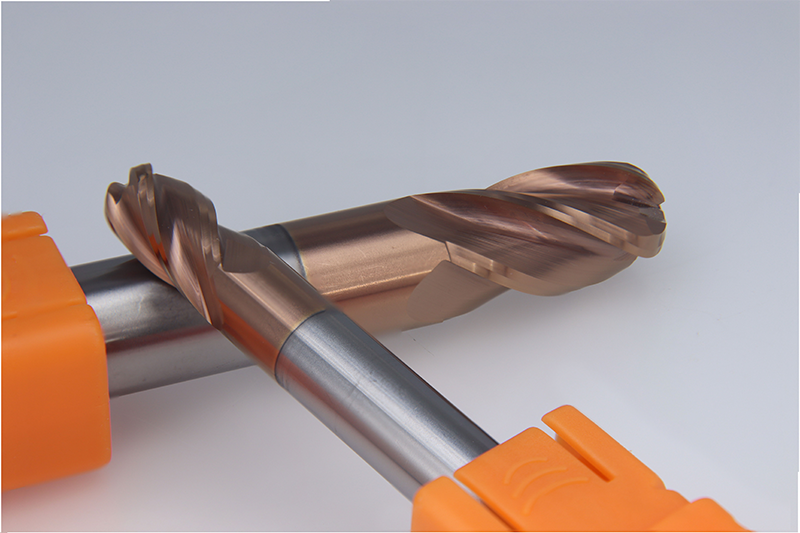

A lub pob qhov ntswg txiavyog lub tshuab txiav kawg nrog lub hau hemispherical. Qhov kev tsim no tso cai rau kev txiav du thiab txuas ntxiv, ua rau nws zoo tagnrho rau kev siv cov duab peb-seem. cov tshuab txiav pob qhov ntswg feem ntau siv rau ntawm CNC (computer numerical control) milling tshuab, qhov twg qhov tseeb thiab rov ua dua yog qhov tseem ceeb. Lub duab tshwj xeeb ntawm lub tshuab txiav no ua rau nws tsim cov duab sib txawv, ua rau nws nyiam ntawm cov engineers thiab cov neeg tsim qauv thoob plaws ntau yam kev lag luam.

Daim ntawv thov ntawm cov pob kawg mills

Cov tshuab txiav pob zeb muaj ntau yam siv tau thiab siv tau rau ntau yam kev siv. Qee qhov kev siv feem ntau suav nrog:

1. Kev Tsim 3D: Qhov zoo tshaj plaws ntawm lub tshuab txiav pob yog nws lub peev xwm los tsim cov duab 3D nyuaj. Txawm hais tias carving ib lub pwm lossis machining ib feem nrog cov kab nkhaus nyuaj, lub tshuab txiav pob zoo heev ntawm kev tsim cov nto du thiab cov yam ntxwv zoo.

2. Kev Ua Kom Tiav Ntawm Qhov Chaw: Lub taub hau puag ncig ntawm lub tshuab sib tsoo pob ua rau muaj kev ua tiav ntawm qhov chaw zoo heev. Nws tshem tawm cov khoom thaum tseem tshuav qhov chaw zoo, txo qhov xav tau kev ua haujlwm polishing lossis kev sib tsoo ntxiv.

3. Kev Sib Tsoo: cov tshuab txiav pob qhov ntswg kuj tsim nyog rau kev ua haujlwm sib tsoo, uas yog kev tshem tawm cov khoom siv los ntawm thaj chaw tshwj xeeb los ua ib qho groove. Tus qauv tsim ntawm lub tshuab txiav milling tso cai rau kev tshem tawm cov khoom siv tau zoo thaum tswj hwm cov duab xav tau.

4. Kev Txiav: Rau cov ntawv thov uas xav tau kev txiav zoo, cov tshuab txiav pob tuaj yeem tsim cov kab zoo thiab cov qauv tsim nyuaj. Qhov no ua rau nws yog qhov kev xaiv nrov rau cov khoom dai kom zoo nkauj ntawm ntau yam khoom.

Cov txiaj ntsig ntawm kev siv lub tshuab zeb kawg pob

Muaj ntau yam zoo rau kev siv lub tshuab zeb kawg hauv koj cov txheej txheem machining:

- Kev Ntsuas Tseeb: Cov pob zeb kawg tau tsim los tswj qhov tob thiab lub kaum sab xis ntawm kev txiav, ua rau muaj qhov loj me thiab cov nplaim du.

- Kev Siv Tau Ntau Yam: Nrog lub peev xwm los ua ntau yam haujlwm los ntawm kev txiav mus rau kev txiav, cov tshuab txiav pob kawg tuaj yeem siv rau ntau qhov project, txo qhov xav tau ntau yam cuab yeej.

- Txo qhov hnav ntawm cov cuab yeej: Qhov kev txiav txuas ntxiv ntawm cov tshuab txiav pob qhov ntswg txo qhov hnav ntawm cov cuab yeej, yog li ua rau lub cuab yeej siv tau ntev dua thiab txo cov nqi hloov.

- Kev Ua Haujlwm Zoo Dua: Cov duab nyuaj tuaj yeem ua tiav hauv tsawg lub sijhawm, yog li txhim kho kev ua tiav tag nrho thiab txuag lub sijhawm thiab cov peev txheej.

Xaus lus

Xaus lus, cov tshuab txiav pob zeb yog ib yam cuab yeej tseem ceeb hauv ntiaj teb kev siv tshuab niaj hnub no. Lawv txoj kev tsim tshwj xeeb thiab kev ua tau ntau yam ua rau lawv zoo tagnrho rau ntau yam kev siv, txij li 3D contouring mus rau qhov tiav ntawm qhov chaw. Raws li kev lag luam txuas ntxiv xav tau qhov tseeb thiab kev ua haujlwm zoo dua, cov tshuab txiav pob zeb yuav txuas ntxiv ua ib qho cuab yeej tseem ceeb hauv kev ua haujlwm machining. Txawm hais tias koj yog tus kws kho tshuab uas muaj kev paub dhau los lossis tshiab rau hauv daim teb no, kev nkag siab txog cov yam ntxwv thiab cov txiaj ntsig ntawm cov tshuab txiav pob zeb tuaj yeem pab koj txiav txim siab tau zoo thiab coj koj cov haujlwm machining mus rau qhov siab tshiab. Txais yuav qhov tseeb thiab kev ua tau ntau yam ntawm cov tshuab txiav pob zeb thiab saib koj cov peev xwm machining nce siab.

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-24-2024