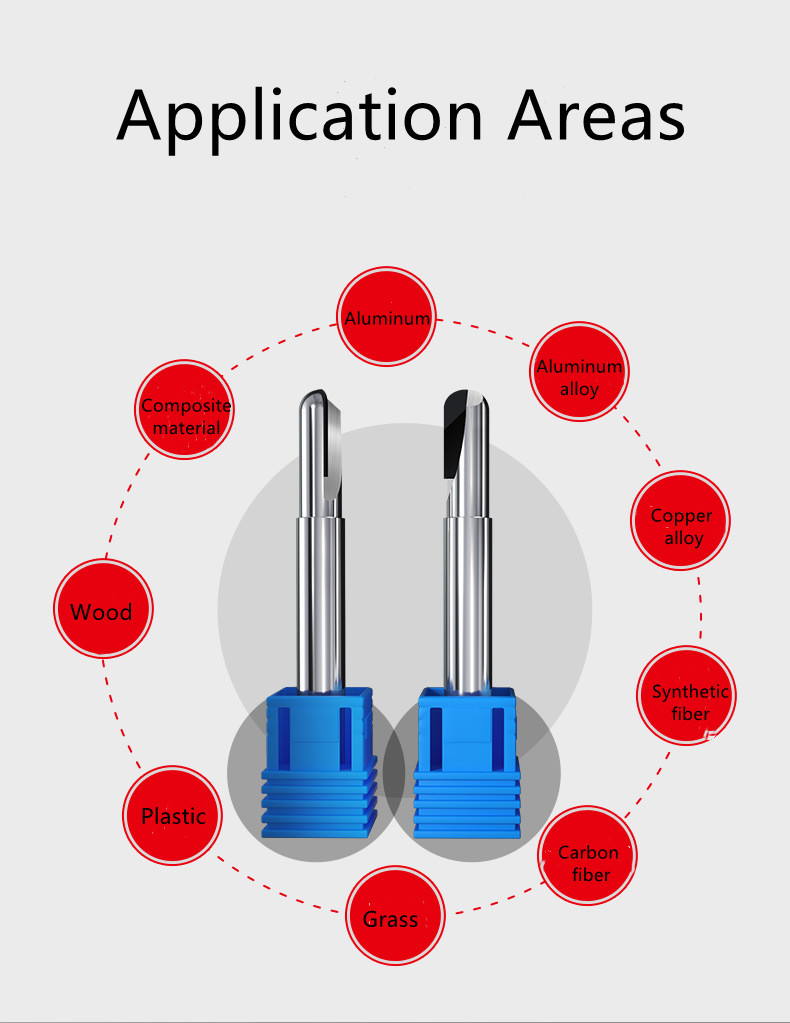

Kub muag khoom PCD CNC pob qhov ntswg Milling Cutter nrog kho vajtse txiav cov cuab yeej

Kub Muag Khoom PCD CNC Pob Qhov Ntswg Milling Cutter Nrog Cov Cuab Yeej Txiav Kho Vajtse

Pob zeb diamond hardness siab yog xaiv ua raw khoom, cov cuab yeej ntse, lub neej ntev kev pabcuam;

Kev siv tshuab sib tsoo siab heev rau kev sib tsoo nto;

Kev raug siab dua thiab kev tiv taus kub;

High precision tiaj tus hauv qab concentricity siab carving ntau peb-dimensional, ntse tsis tawg ston tsis muaj cim;

Tungsten hlau shank, zoo dua stability;

Nta:

1.Raws li cov khoom siv abrasive precision, siv rau kev sib tsoo thiab polishing siab.

2.Ua ib qho tshuaj ntxiv rau txheej, nws yog siv rau txheej ntawm cov pwm hlau, cov cuab yeej, thiab lwm yam, uas tuaj yeem txhim kho qhov siab ntawm qhov chaw abrasiveness, qhov nyuaj ntawm qhov chaw, thiab txuas ntxiv lub neej kev pabcuam.

3.Nws feem ntau yog siv rau kev sib tsoo. Feem ntau nws yog teeb tsa ua kua sib tsoo. Nws kuj tseem siv tau los ua riam. Kev txiav tsis yooj yim ua rau muaj chipping.