Nasarar masana'antu ta dogara ne akan sabbin na'urorin haƙa kwarara (wanda aka sani dathermal gogayya rawar soja bits ko flowdrill) yana canza yadda masana'antu ke ƙirƙirar zare masu ƙarfi da aminci a cikin ƙarfe mai siriri da bututu. Wannan fasahar da ta dogara da gogayya ta kawar da buƙatar haƙa da matsewa na gargajiya, tana ba da gagarumin riba a ƙarfi, gudu, da inganci a farashi, musamman a fannin kera motoci, sararin samaniya, da na'urorin lantarki.

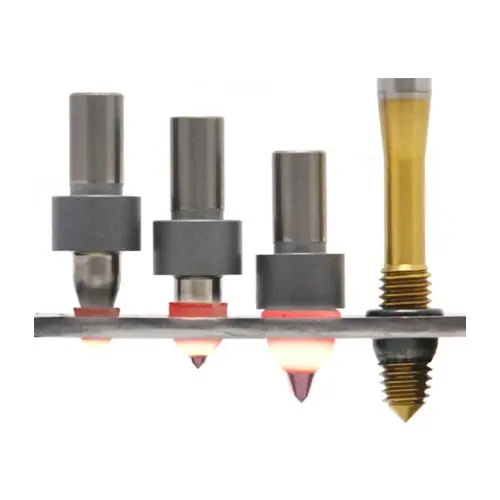

Babban ƙirƙira yana cikin tsari na musamman da waɗannan ƙananan sassa na musamman suka samar. Ba kamar na'urorin haƙa rami na gargajiya waɗanda ke yankewa da cire kayan aiki ba, injin haƙa rami yana samar da zafi mai zafi ta hanyar haɗakar saurin juyawa mai ƙarfi da matsin lamba na axial. Yayin da ƙarshen tungsten carbide mai siffar musamman ya haɗu da saman aikin, gogayya tana dumama ƙarfen da ke ƙarƙashinsa cikin sauri - yawanci ƙarfe, bakin ƙarfe, aluminum, ko ƙarfe - zuwa yanayin filastik ɗinsa (kimanin 600-900°C ya danganta da kayan).

Wannan bushing ɗin da aka ƙera yana da matuƙar muhimmanci. Yawanci yana faɗaɗa har sau 3 na kauri na asali na kayan tushe. Misali, zare mai kauri 2mm yana haifar da ƙwallo mai ƙarfi mai tsayi 6mm. Wannan yana ƙara zurfin haɗin zaren sosai fiye da yadda zai yiwu idan kauri na kayan kawai ya ƙaru.

Bayan samuwar bushing ɗin, aikin yakan ci gaba ba tare da wata matsala ba. Bututun da aka saba amfani da shi yana bin diddiginsa.ramin haƙa kwarara, ko dai nan take a cikin zagayowar injin guda ɗaya (a kan kayan aiki masu dacewa) ko kuma a wani aiki na gaba. Famfon yana yanke zare daidai kai tsaye zuwa cikin sabon bushing ɗin da aka ƙirƙira, mai kauri bango. Tunda bushing ɗin wani ɓangare ne na tsarin hatsi na asali, ba ƙarin sakawa ba, zaren da aka samu yana da babban daidaito da ƙarfi mai girma.

Manyan Fa'idodi na Tuki Ɗauka:

Ƙarfin da Ba a Daidaita ba a cikin Siraran Kaya: Bushing ɗin 3x yana ba da kyakkyawar hulɗar zare idan aka kwatanta da taɓa kauri tushe kai tsaye ko amfani da abubuwan sakawa.

Sauri & Inganci: Yana haɗa yin ramuka da ƙirƙirar bushing zuwa aiki ɗaya mai sauri (sau da yawa daƙiƙa a kowace rami), yana kawar da haƙa daban, cire burbushin, da kuma shigar da matakan shigarwa.

Tanadin Kayan Aiki: Ba a samar da guntu a lokacin haƙa kwararar ruwa ba, wanda hakan ke rage sharar kayan aiki.

Haɗaɗɗun Haɗaɗɗu: Kayan da aka cire daga ramin suna gudana sosai a kusa da ramin, wanda sau da yawa yana samar da haɗin da ba ya zubar da ruwa wanda ya dace da amfani da ruwa ko matsi.

Rage Kayan Aiki: Yana kawar da buƙatar goro, goro mai walda, ko kayan sakawa masu rivet, yana sauƙaƙa BOMs da dabaru.

Tsarin Tsaftacewa: Ƙananan kwakwalwan kwamfuta kuma babu buƙatar yanke ruwa a aikace-aikace da yawa (wani lokacin ana amfani da man shafawa don rayuwar bit ko takamaiman kayan aiki).

Aikace-aikace Yawa: Fasaha tana samun karɓuwa cikin sauri duk inda kayan siriri masu sauƙi ke buƙatar haɗin zare masu ƙarfi:

Motoci: Tirelolin batirin abin hawa na lantarki, sassan chassis, maƙallan ƙarfe, tsarin fitar da hayaki, firam ɗin wurin zama.

Aerospace: Faifan ciki, bututun iska, da maƙallan tsari masu sauƙi.

Kayan lantarki: Rakunan uwar garken, bangarorin kabad, wuraren wanke-wanke.

HVAC: Haɗin bututun ƙarfe na takarda, maƙallan ƙarfe.

Kayan Daki da Kayan Aiki: Firam ɗin gini da ke buƙatar ɓoyayyun wuraren ɗaurewa masu ƙarfi.

Masu kera na'urorin haƙa ramin kwarara suna ci gaba da inganta yanayin ƙasa, shafi, da kayan aiki don tsawaita tsawon rayuwar kayan aiki, inganta aiki akan ƙarfe masu tasowa, da kuma inganta tsarin aiki ta atomatik. Yayin da masana'antu ke ci gaba da bin ƙa'idodin rage nauyi da ingancin masana'antu, haƙa ramin gogayya mai zafi, wanda ke aiki ta hanyar sabbin fasahohi.rawar ruwabit, yana tabbatar da cewa mafita ce mai mahimmanci don ƙirƙirar zare masu aiki mai kyau inda a da ba su da yiwuwa ko kuma ba su da amfani. Zamanin gwagwarmaya da zare masu rauni a cikin siririn zanen gado yana ba da hanya ga ƙarfi da sauƙin bushings da aka samar da gogayya.

Lokacin Saƙo: Yuli-30-2025