A cikin duniyar kera kayan lantarki mai sauri, inda daidaiton matakin micron ke bayyana nasara, gabatar da Next-Gen PCB Board Drill Bits ya nuna babban tsalle a cikin kera allon da'ira. An ƙera su don haƙa, sassaka, da injinan micro akan allunan da'ira da aka buga (PCBs) da sauran substrates masu siriri sosai, waɗannan Tungsten SteelMini Rakiyar PCBKayan aiki suna haɗa kayan da aka yi amfani da su a fannin sararin samaniya da fasahar daidaita girgizar ƙasa don sake fasalta inganci da tsawon rai a fannin samar da kayayyaki masu yawa.

Ingantaccen Injiniya: Dalilin da Ya Sa Karfe Tungsten Yake da Muhimmanci

A tsakiyar waɗannan injinan haƙa rami akwai tungsten carbide mai tsabta (WC), wani abu da aka zaɓa saboda haɗakar tauri mara misaltuwa (HRA 92), juriyar lalacewa, da kuma ingancin tsarinsa. Ba kamar injinan HSS (Babban Saurin Karfe) na gargajiya ba, wannan tsarin ƙarfe na tungsten yana ba da:

Tsawon Rayuwa Sau 3: Yana jure wa zagayowar haƙa rami sama da 15,000 akan allon fiberglass na FR-4 ba tare da lalata gefen ba.

Tsarin Ƙananan Hatsi: Hatsin carbide mai ƙasa da 0.5µm yana tabbatar da gefuna masu kaifi, suna cimma ƙananan diamita na ramuka kamar 0.1mm tare da juriyar ±0.005mm.

Tsarin hana karyewar ƙashi: Tsarin ƙashi mai ƙarfi yana hana karyewar ƙashi yayin ayyukan RPM mai ƙarfi (30,000–60,000), koda a cikin kayan PCB masu karyewar ƙashi.

Gwaji na ɓangare na uku da Cibiyar Fasaha ta Precision Machining ta tabbatar ya tabbatar da cewa waɗannan bits ɗin suna kiyaye saman Ra 0.8µm bayan ramuka 10,000 - muhimmin abu ne don tabbatar da ingancin siginar mita mai yawa a cikin na'urorin 5G da IoT.

Kwanciyar Hankali a Girgizar Ƙasa: Yankewa Ba Tare da Yarjejeniya ba

Hako PCB yana buƙatar cikakken kwanciyar hankali don hana "tafiya" ko kuskuren ramuka. Tsarin Gefen Blade na Girgizar Ƙasa ya magance wannan ta hanyar:

Tsarin Saurare mara daidaituwa: Yana daidaita fitar da guntu da rage girgiza, yana rage ƙarfin gefe da kashi 40%.

Kusurwar Helix Mai Rufi Nano: Helix mai tsawon digiri 30 tare da rufin TiAlN yana rage yawan taruwar zafi (<70°C) yayin aiki akai-akai.

Magance Raƙuman Ruwa: Ƙananan tashoshi masu etched laser suna lalata mitoci masu jituwa, suna tabbatar da daidaiton matsayi a cikin 5µm a cikin PCBs masu layuka 10.

A cikin gwajin damuwa da aka yi na haƙa ramuka 0.3mm ta cikin allunan da aka lulluɓe da aluminum na 2mm, waɗannan ragowa sun nuna babu karkacewa a kan zagayowar 500 a jere - abin da masu fafatawa ba su iya kwatantawa ba.

Aikace-aikace a Faɗin Masana'antu

Kayan Lantarki na Masu Amfani

Ga masana'antun motherboard na wayar salula:

Ƙananan Vias na 0.2mm: An cimma ƙimar yawan amfanin ƙasa da kashi 99.9% akan allunan HDI masu layuka 12.

Yawan Ciyarwa cikin Sauri 20%: An kunna shi ta hanyar rage gogayya da toshewar guntu.

Na'urorin Lantarki na Motoci

A cikin samar da module ɗin wutar lantarki na EV:

Ingancin Rami: An kiyaye ci gaba da wutar lantarki 100% a cikin substrates masu kauri 1.6mm mai kauri.

Aiki Ba Tare da Sanyaya Ba: Ƙarfin haƙa busasshiyar na hana gurɓatawa a cikin tsarin sarrafa batir da aka rufe.

Tashar Jiragen Sama da Tsaro

Hako ramukan 0.15mm a cikin da'irorin lanƙwasa na polyimide:

Babu Rage Tsaftacewa: Ko da a cikin yanayin zafi mai zafi na 200°C.

Tsarin Garkuwar EMI: Zane-zanen da aka tsara don yadudduka na kariyar RF da aka yi da graphene.

Bayanan Fasaha

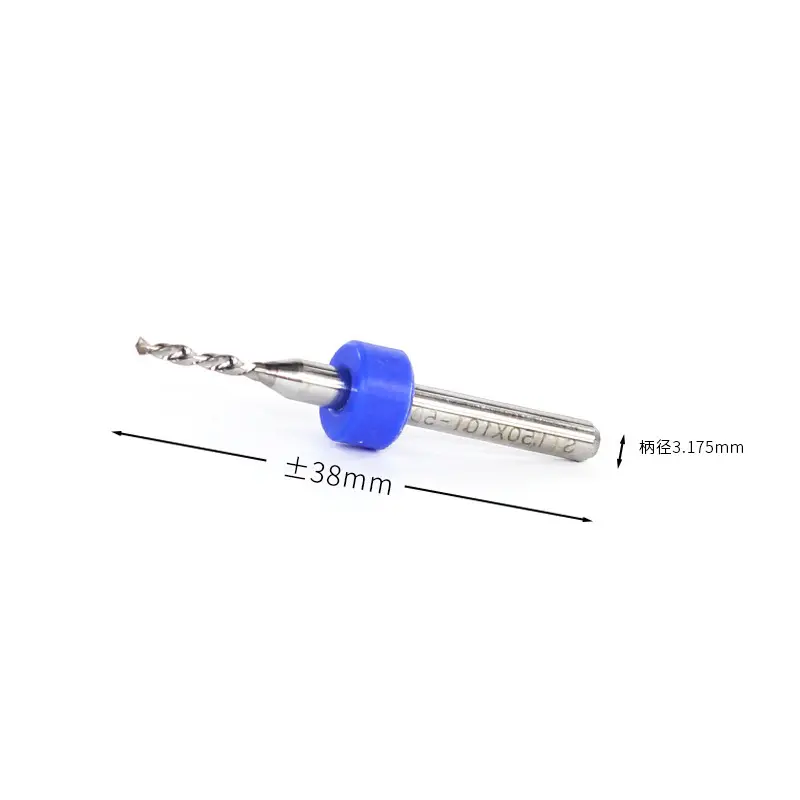

Nisan Diamita: 0.1mm–3.175mm (0.004"–1/8")

Nau'in Shank: Daidaitaccen 3.175mm (1/8") ko dacewa da collet na ER na musamman

Zaɓuɓɓukan Rufi: TiN (zinariya), TiCN (shuɗi), ko Carbon Mai Kama da Diamond (DLC)

Matsakaicin RPM: 80,000 (ya danganta da diamita)

Karfinsu: Injinan haƙa CNC, mashinan haƙa PCB ta atomatik, kayan aikin juyawa na hannu

An Sake Fahimtar Ingancin Kuɗi

Wani bincike da wani babban kamfanin kera PCB na Taiwan ya gudanar ya nuna cewa:

Ajiyar Kuɗi ta Shekara-shekara: Rage maye gurbin injinan haƙa rami (daga saiti 12 zuwa 4 a kowace shekara).

Rage Makamashi 15%: Bukatun ƙarfin juyi mai ƙanƙanta.

Ba a sake yin aiki ba: An cire dala $220,000 a kowace shekara a cikin allunan da aka lalata daga aikin haƙa rami.

Dorewa da aka Gina a ciki

Marufi Mai Sake Amfani: Tiren kumfa mai lalacewa 100%.

Bin ƙa'idodin RoHS & REACH: Ba ya ƙunshe da gubar, cadmium, da sauran abubuwa masu haɗari.

Tsawon Rayuwar Kayan Aiki: Rage amfani da tungsten 60% idan aka kwatanta da na'urorin motsa jiki na yau da kullun.

Shaidar Mai Amfani

"Sauya zuwa waɗannan guntun ƙarfe na tungsten ya kasance abin canji," in ji Hiroshi Tanaka, Manajan Samarwa a wani kamfanin kera na'urori masu auna firikwensin da ke Kyoto. "Muna haƙa ramuka 20,000 a kowane aiki ba tare da wani canjin kayan aiki ba - wani abu da ba za a iya tunaninsa ba tare da tsoffin injinan HSS ɗinmu. Tsarin girgizar ƙasa kaɗai ya rage ƙin matsayin raminmu da kashi 95%.

Me Yasa Zabi Wadannan PCB Board Ramin Ragowa?

Daidaito Mai Karyewa: Don daidaito irin na laser a cikin allunan haɗin kai mai yawa (HDI).

Sauri Ba Tare da Sadaukarwa ba: Haƙa ramuka 0.3mm a ramuka 400 a minti ɗaya ba tare da rage ingancin gefen ba.

Daidaituwa ta Duniya: Yana aiki da FR-4, Rogers, aluminum, har ma da laminates masu ƙarfi da gilashi.

Tsarin Tabbatar da Tabbaci na Nan Gaba: A shirye don kayan PCB na zamani kamar su dielectrics marasa halogen da ƙarancin asarar nauyi.

Kammalawa

A cikin masana'antar da kowace micron ke nuna riba da aiki, waɗannan Tungsten SteelRagowar Rawar Jirgin PCBsun fi kayan aiki - suna da fa'ida ta dabaru. Ta hanyar haɗa kimiyyar kayan aiki da injiniyan kwanciyar hankali, suna ƙarfafa masana'antun su matsawa iyakokin rage yawan aiki yayin da suke rage yawan aiki.

Lokacin Saƙo: Maris-21-2025