HSS Tap M3, M4, M5, M6, M8, M10 Ramin Tap Bits

BAYANIN KAYAYYAKI

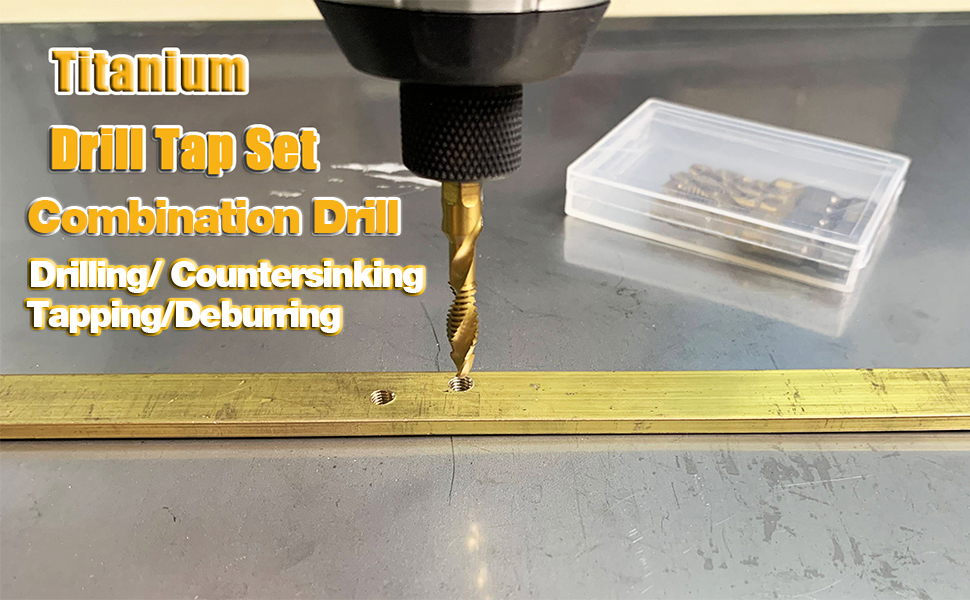

A ƙarshen famfon (famfon zare) akwai wani abin haƙa rami, wanda shine famfon da ke da inganci sosai (famfon zare) don ci gaba da haƙa rami da kuma taɓawa don kammala aiki a lokaci guda.

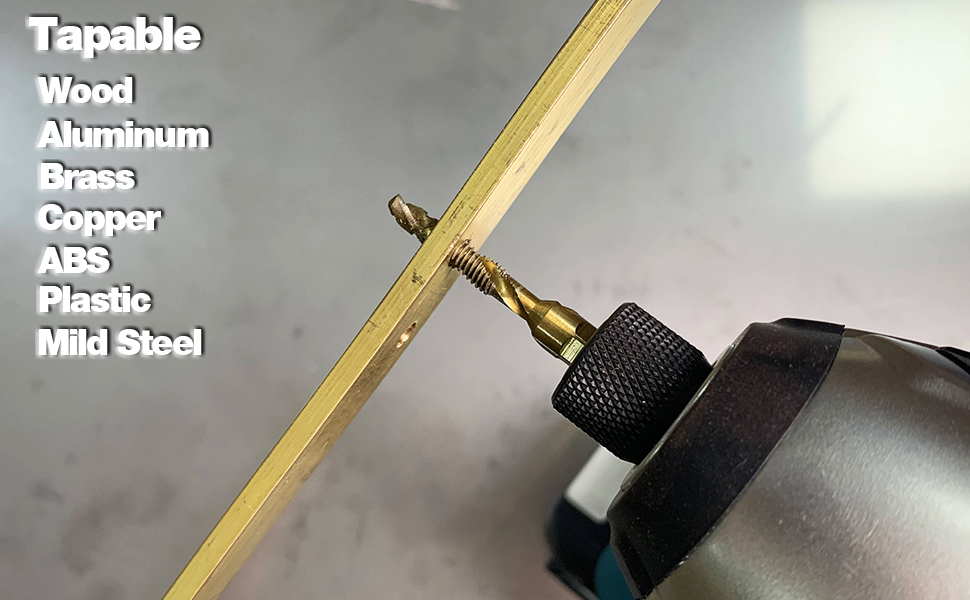

Kayan ƙarfe mai sauri 4341, wanda ya dace da filastik, PVC, itace da sauran kayan aiki.

Kayan ƙarfe mai sauri 6542, wanda ya dace da ƙarfe masu laushi kamar ƙarfe na aluminum, ƙarfe na tin, sassa daban-daban na jan ƙarfe, da ƙarfe mai siminti.

Kayan ƙarfe mai sauri na M35, wanda ake amfani da shi don kayan tauri kamar farantin ƙarfe, ƙarfe mai siminti, 204, bakin ƙarfe mai sirara 304

SHAWARA GAME DA AMFANI A BITA

- Ya dace da gyaran mota da injina inda aka ƙayyade wayoyi masu inci masu haɗin UNC.

– Ana amfani da su kamar lathe. Suna da sauri, kuma gabaɗaya sun fi daidaito saboda an kawar da kuskuren ɗan adam.

- Ana iya haɗa shi da injin motsa jiki.

- Ya dace don amfani a cikin aikin haƙori na hannu

| Alamar kasuwanci | MSK | Shafi | TiCN; Ti; Cobalt |

| Sunan Samfuri | Ramin Taɓawa | Nau'in Zaren | Zaren da ba shi da kauri |

| Kayan Aiki | HSS 6542/4341/4241 | Amfani | Rawar Hannu |

FA'IDA

1.Kaifi kuma babu ƙura

Gefen ya ɗauki tsarin tsagi madaidaiciya, wanda ke rage lalacewa yayin yankewa, kuma kan yankan ya fi kaifi da dorewa.

2. Nika gaba ɗaya

Ana niƙa gaba ɗaya bayan an yi amfani da zafi, kuma saman ruwan wuka yana da santsi, juriyar cire guntu ƙarami ne, kuma taurin yana da yawa.

3. Zaɓin kayan aiki mai kyau

Ta amfani da kayan aiki masu kyau waɗanda ke ɗauke da sinadarin cobalt, yana da fa'idodin ƙarfi mai yawa, ƙarfin tauri mai yawa da juriyar lalacewa.

4. Faɗin aikace-aikace

Ana iya amfani da bututun sarewa madaidaiciya masu ɗauke da cobalt don haƙa kayan aiki daban-daban, tare da cikakken jerin samfura.

5. Tsarin tsagi mai karkace

An ƙera shi daga kayan ƙarfe mai sauri, saman an rufe shi da titanium, kuma tsawon rayuwar sabis ɗin yana da tsawo.

| Ƙayyadewa | Jimlar tsawon (mm) | Tsawon Ramin (mm) | Tsawon sarewa (mm) | Nauyin Tsafta (g/pc) |

| M3 | 65 | 7.5 | 13.5 | 12.5 |

| M4 | 65 | 8.5 | 14.5 | 12.6 |

| M5 | 69 | 9.5 | 15.5 | 12.8 |

| M6 | 69 | 10 | 17.5 | 13.6 |

| M8 | 72 | 14.5 | 20 | 15.2 |

| M10 | 72 | 14.5 | 22 | 17.8 |