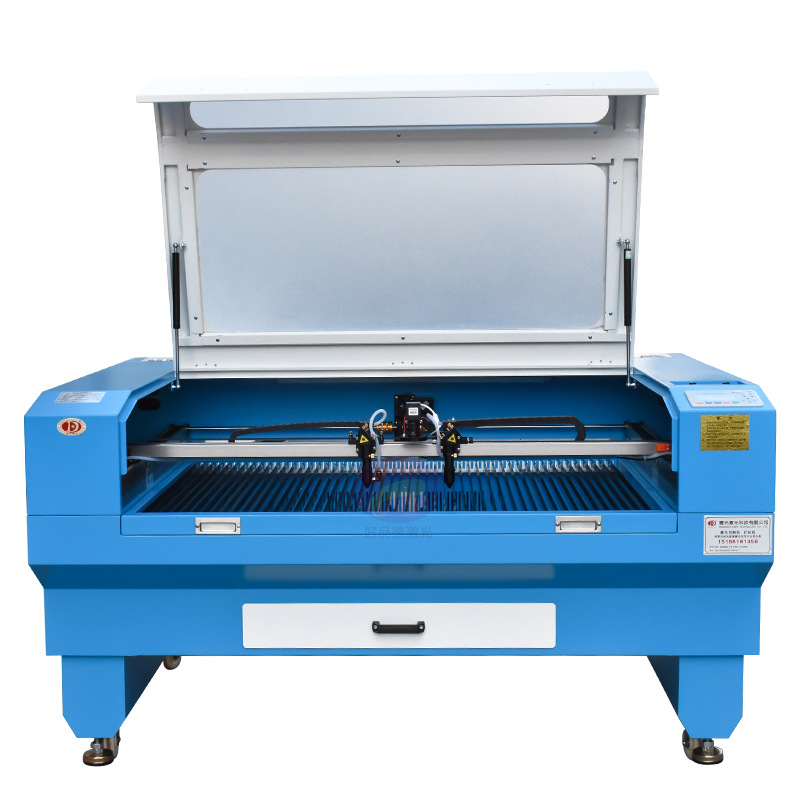

Good Quality 450W Co2 Laser Wood Cutting For Wood

Features

1. Faster and more efficient

High power suitable for cutting thick planks

2.450W high power cutting

Stable speed of light, no stray light, stronger penetrating power

3. Chiller

High cooling capacity chiller: suitable for high power use, can automatically cool down and play a protective role

4. Laser head

High-quality laser head: suitable for high-power use, better quality and more durable

5. Premium lenses

Suitable for high power use, better quality and higher efficiency

Preparation before using the laser cutting machine

1. Check whether the power supply voltage is consistent with the rated voltage of the machine before use, so as to avoid unnecessary damage.

2. Check whether there is foreign matter residue on the machine table, so as not to affect the normal cutting operation.

3. Check whether the cooling water pressure and water temperature of the chiller are normal.

4. Check whether the cutting auxiliary gas pressure is normal.

How to use the laser cutting machine

1. Fix the material to be cut on the work surface of the laser cutting machine.

2. According to the material and thickness of the metal sheet, adjust the equipment parameters accordingly.

3. Select the appropriate lenses and nozzles, and check them before starting the machine to check their integrity and cleanliness.

4. Adjust the cutting head to the appropriate focus position according to the cutting thickness and cutting requirements.

5. Select the appropriate cutting gas and check whether the gas ejection state is good.

6. Try to cut the material. After the material is cut, check the verticality, roughness of the cut surface and whether there is burr or slag.

7. Analyze the cutting surface and adjust the cutting parameters accordingly until the cutting process of the sample meets the standard.

8. Perform the programming of the workpiece drawings and the layout of the whole board cutting, and import the cutting software system.

9. Adjust the cutting head and focus distance, prepare auxiliary gas, and start cutting.

10. Check the process of the sample, and adjust the parameters in time if there is any problem, until the cutting meets the process requirements.